Site foundation treatment

1. Before laying the HDPE geomembrane, the laying base shall be comprehensively inspected together with relevant departments. The laying base shall be solid and flat. There shall be no tree roots, rubble, stones, concrete particles, reinforcement heads, glass chips and other debris that may damage the geomembrane within the vertical depth of 25 mm. Use a wheel compactor to compact to remove car marks, footprints and ground bumps. In addition, the ground bulges larger than 12mm shall also be chipped or compacted.

2. When HDPE geomembrane is laid on the backfill, the compactness of the backfill shall not be less than 95%.

3.The site foundation shall be free of water seepage, sludge, ponding, organic residue and harmful substances that may cause environmental pollution. The corner of the base shall be smooth. Generally, its arc radius shall not be less than 500 mm.

Technical requirements for HDPE geomembrane installation.

1. The laying and welding of HDPE geomembrane should be carried out in the weather where the temperature is above 5 ℃ and the wind force is below Grade 4 without rain or snow.

2. The construction process of HDPE geomembrane shall be carried out in the following order: geomembrane laying → lapping welding joints → welding → on-site inspection → repair → re inspection → backfilling.

3. The overlapping width of the joints between membranes shall not be less than 80mm. Generally, the joint arrangement direction shall be equal to the maximum slope line, that is, it shall be arranged along the slope direction.

4. During the laying of HDPE geomembrane, artificial wrinkles shall be avoided as far as possible. When laying HDPE geomembrane, the expansion deformation caused by temperature change shall be reserved according to the local temperature change range and the performance requirements of HDPE geomembrane. In addition, the expansion amount of geomembrane shall be reserved according to the site terrain and the laying of geomembrane to adapt to the uneven settlement of the foundation.

5. After the HDPE geomembrane is laid, walking on the membrane surface and handling tools shall be minimized. Objects that can cause harm to the HDPE geomembrane shall not be placed on the geomembrane or carried on the geomembrane to avoid accidental damage to the HDPE membrane.

6. All personnel on the HDPE film construction site shall not smoke, wear shoes with nails or high-heeled hard soled shoes to walk on the film surface, or engage in any activity that may damage the impermeable film.

7. After the HDPE geomembrane is laid and before the protective layer is covered, a 20-40Kg sand bag shall be placed at the corner of the membrane every 2-5m to prevent the geomembrane from being blown by the wind.

8. HDPE geomembrane shall be natural and close to the supporting layer, and shall not be folded or suspended in the air.

9. When the geomembrane is constructed in sections, the upper layer shall be covered in time after laying, and the exposed time in the air shall not exceed 30 days.

The anchoring of HDPE geomembrane shall be carried out according to the design. In places with complex terrain in the project, the construction unit shall propose other anchoring methods, which shall be carried out after obtaining the consent of the design unit and the supervision unit.

HDPE geomembrane welding requirements:

1. The overlapping surface of HDPE geomembrane weld shall be free of dirt, sand, water (including dew) and other impurities that affect the welding quality, and shall be cleaned up during welding.

2. At the beginning of welding every day (in the morning and after lunch break), test welding must be carried out on the site first, and formal welding can only be carried out after it is qualified.

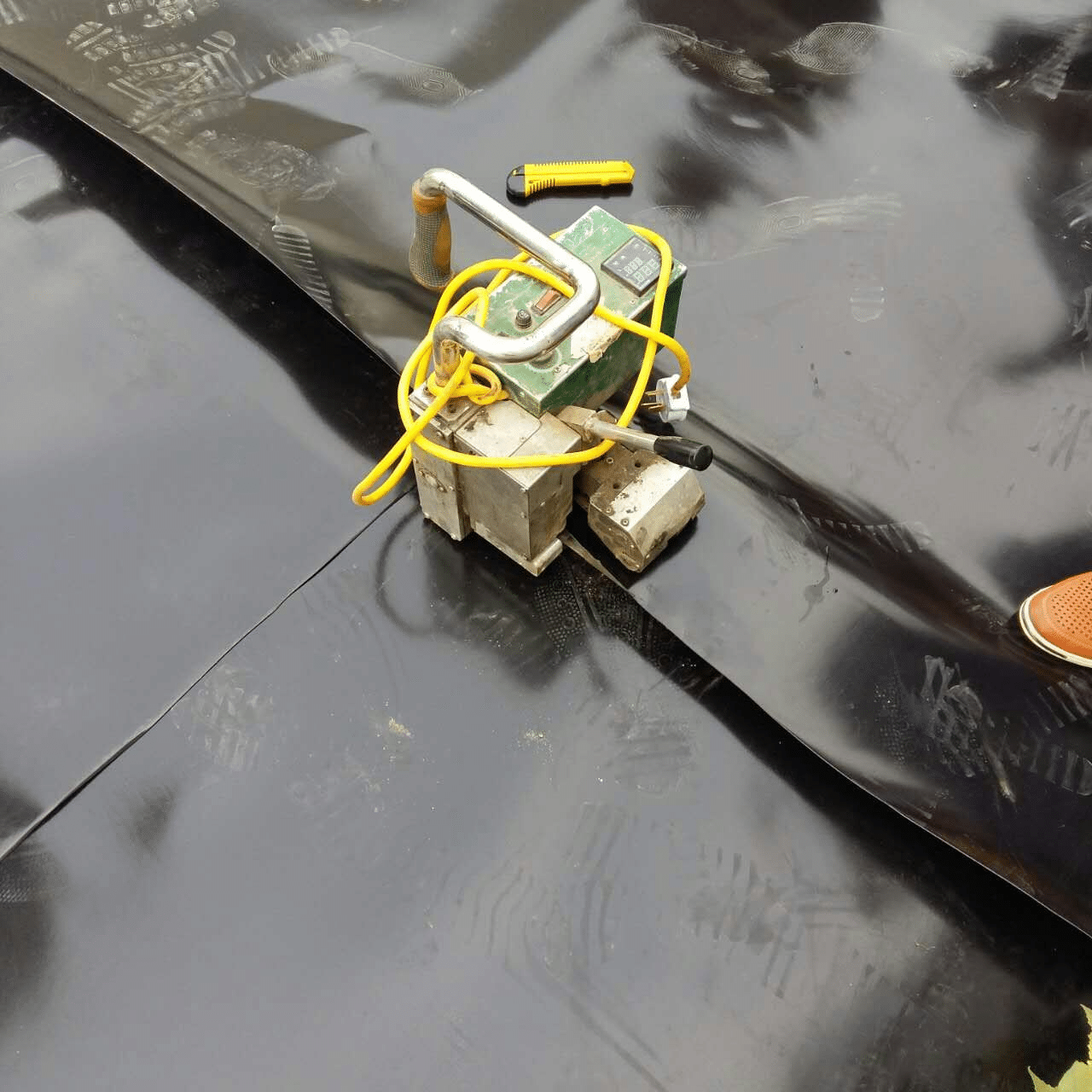

3. The HDPE geomembrane should be welded by double track hot-melt welding machine, and the extrusion welding or hot-air gun welding should only be used in places where the repair, covering or hot-melt welding machine cannot reach.

4. During construction, the working temperature and speed of the welding machine shall be adjusted and controlled at any time according to the temperature and material properties.

5.HDPE film at the weld shall be welded as a whole, and there shall be no false welding, missing welding or excessive welding. The connected two layers of HDPE geomembrane must be lapped flat and gentle.

Weld quality control

With the progress of construction, it is required to check the welding quality of HDPE film in time, and repair welding with hot air gun or plastic welding gun at any time for missing welding and faulty welding parts. The specific methods are as follows:

1.The inspection is carried out in three steps, namely visual inspection, inflation inspection and damage test.

2. Visual inspection: check whether the two welds are flat, clear, wrinkle free, transparent, slag free, bubble, leak point, melting point or weld bead.

Visual inspection is mainly to carefully inspect the appearance of the laid geomembrane, weld quality, T-shaped welding, substrate debris, etc. All construction personnel shall carry out this work in all construction processes.

3. In addition to visual inspection, vacuum inspection shall be adopted for the tightness of all welds, and self inspection shall be strengthened for the parts that cannot be inspected by vacuum.

4. The inflation strength detected by the inflation pressure is 0.25Mpa, and there is no air leakage for 2 minutes. Considering that the coiled material is soft and easy to deform, the allowable pressure drop is 20%

5. When conducting tensile test on the sample taken from the double rail weld, the standard is that the weld is not torn but the mother is torn and damaged during the peel and shear tests. At this time, the welding is qualified. If the sample is unqualified, a second piece shall be taken from the original weld. If three pieces are unqualified, the whole weld shall be reworked.

6. Samples passing the test shall be submitted to the Owner, the General Contractor and relevant units for filing.

7. Defects found in visual inspection, inflation detection and damage test shall be repaired in time. Those that cannot be repaired immediately shall be marked to prevent omission during repair.

8. In the appearance inspection, in case of defects such as holes on the membrane surface and missing welding, faulty welding and damage during welding, fresh base metal shall be used to repair in time, and each side of the repaired scar shall exceed the damaged part by 10-20cm. Make records.

9. For the repaired weld, detailed visual inspection shall be carried out generally, and release shall be carried out after the repair is confirmed to be reliable.

Post time: Dec-14-2022